Battery Tech Article

Recycling Lithium-ion Battery Cathodes Using Deep Eutectic Solvents

Technology Overview

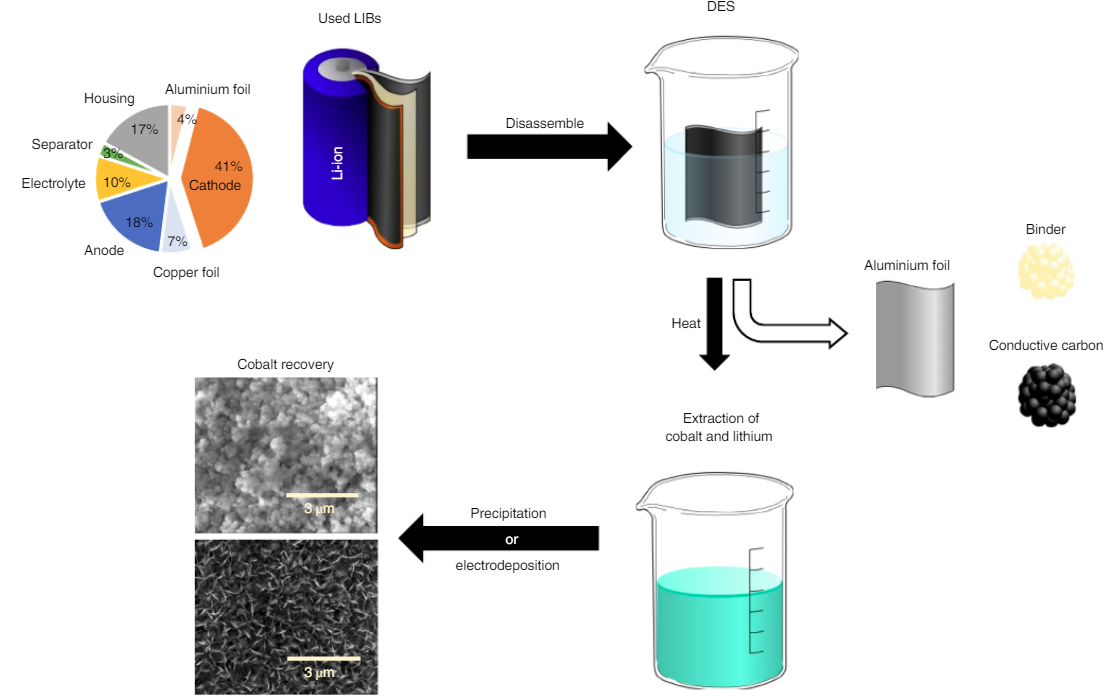

As the consumption of lithium-ion batteries (LIBs) for the transportation and consumer electronics sectors continues to grow, so does the pile of battery waste. Lithium-ion battery waste retains value particularly in the form of metal ions in the cathode part of the device, but few standardised methods exist to extract, recover, and reuse these precious metals. Such metals can be extracted using environmentally-friendly deep eutectic solvents which is safer than other corrosive hydrometallurgical methods which typically use strong acids, or high-energy pyrometallurgical methods which incinerate and grind waste battery material at temperatures beyond 1000˚C. The deep eutectic solvents (DES) can be made from commercially available commodities such as choline chloride and ethylene glycol which makes them good candidates for industrial scales. The battery recycling industries could benefit from the use of safer solvents that can still effectively extract and recover precious metals from spent lithium-ion batteries for reuse in other applications.Starting with disassembly of the LIB, cathode waste is inserted into a DES, which is then heated and stirred. Extraction of cobalt and lithiumm ions occurs through dissolution, and at this step, aluminium foil, binder and conductive carbon can be recovered separately when the leachate is filtered. Cobalt compounds can then be recovered either through precipitation or electrodeposition, allowing reutilization of these valuable materials.

Technology Features & Specifications

1. Extraction of valuable metals from lithium cobalt oxide (LCO) and lithium nickel manganese cobalt oxide (NMC) battery chemistries.2. For LCO, the leaching efficiencies of >90% were obtained for both cobalt (15% wt of cathode) and lithium. 3. Aluminium foil and polyvinylidene fluoride (PVDF) binder can be recovered separately. 4. The deep eutectic solvent can act as both an effective leaching and reducing agent, eliminating the need for supporting chemicals and processes to achieve metal extraction

Potential Applications

1. Consumer electronics - e.g. LCO batteries.2. Transportation, i.e. electric vehicles - e.g. NMC batteries.3. Other electronic waste recycling, e.g. mining industries.

Market Trends Opportunities

LIB lifetimes barely surpass 3 years in consumer electronics and 5-10 years in electric vehicles. Large number of spent LIBs are expected to be generated, with 500,000 metric tonnes predicted from China alone by 2020. The LIB recycling market is expected to grow with more than 50 companies with facilities dedicated to LIB recycling to date.

Benefits

Environmental-friendly biodegradeable solvents that are non-toxic to humans can still effectively extract metals of interest. They are therefore safer to use than traditional corrosive solvents and high-temperature incinerators which require not only extensive safety procedures for workers but also scrubbing facilities to manage the effluent waste and toxic fumes that off-gas from these methods.

Key information

Technology Category- Energy - Battery & SuperCapacitor

- Energy - Waste-to-Energy

- Chemicals - Inorganic

- Environment, Clean Air & Water - Biological & Chemical Treatment

- Waste Management & Recycling - Industrial Waste Management

ID Number: TO110651

Source: IPI Singapore