Battery Tech Article

Highly Effective Thermal Management for Battery Systems

Technology Overview

Environmental pollution concerns and high fuel cost is driving the car industry towards Electric Vehicle (EV). Li-ion cell is a common adopted energy source for EV. However, Li-ion cells required proper temperature control to function properly. A key factor that affects the battery is temperature. < 0°C: difficult or impossible for charging >60°C: difficult for discharging and risk of degradation, shortened service life >70°C ~ 90°C: will trigger a self-heating reaction with internal cell faults with risk of thermal runaway, presenting safety hazards.Most Li-ion battery achieves their rated capacity at 20~25°C and their capacity will drop ~10% for every increase of 10°C. Regulating the battery temperature during continuous charge and discharge is a challenge, especially in temperate climates.Existing cooling solutions consist of the battery modules sitting on or attached to heat sinks that are in turn cooled by a coolant loop. The drawbacks are that the cooling efficiency is low, and the effectiveness is poor, since only a small part of each module receives the cooling effect. Besides, heat sinks are generally thick and heavy due to the coolant loop. The result is that temperatures will differ from module to module, cell to cell. Even within the same cell, different regions may have different temperatures.Battery packs used in EVs are constrained by space and weight, so cooling systems for the battery packs must be compact and lightweight, and yet meeting the cooling requirements.Our patent granted technology is able to carry coolant to each individual cell in a compact structure. This ensures consistency and uniformity of heat transfer from each cell in a battery pack, extending their lifespan and safety by allowing them to operate in their optimum temperature range (10 ~ 35°C), Charging and discharging can also take place in all ambient temperature.

Technology Features & Specifications

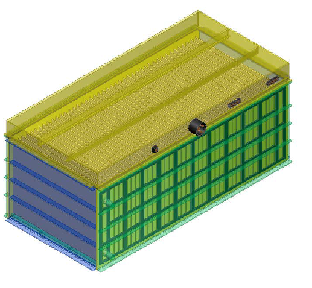

Our system is designed for easy fabrication using standard manufacturing techniques which includes: Aluminium alloy extrusion of MPT (Multi Port Tube - small or micron channel) Aluminium alloy Controlled Atmosphere Brazing (CAB ) techniques.The specifications of our thermal management system integrated with a Li-ion battery pack is as follows: Voltage - 320V Discharge current (maximum) - 200A Energy capacity - 32kWh Energy-to-weight ratio >106Wh/kg Energy-to-volume ratio >127Wh/L Total weight (including ~13kg of coolant) < 300 kg Dimensions (L x W x H, mm) 1030 x 532 x 460This technology is protected via by a PCT patent application. We have received a Singapore patent and is now waiting for grant in the following countries, China, Taiwan, USA, India, Korea, Europe and Japan.

Potential Applications

Our thermal management system can be used in a wide variety of settings, such as: Electric vehicles In-door vehicles (Forklifts, cleaning vehicles) Yachts/ small boats Military applications (Submarines, tanks) Bulk energy storage systems (Wind and solar power generators, UPS)This technology can also be applied to the heat exchange industry, especially for viscous fluid heat exchange.

Market Trends Opportunities

The following factors will promote the growth and widespread adoption of EV: Li-ion power battery technology is advancing more rapidly Government subsidy for EV purchase, and build charging stations and battery swap station. Every car manufacturer had invested in EV, and is rolling out their EV modelsFrom industry statistics and forecasts, the trend of EV adoption will likely take off from 2015 onwards. The general consensus is that 6 ~ 8% of new car sales will be that of electric cars by 2020. This means annual sales of 5 ~ 6 million EVs from 2020 onwards.

Benefits

As described above, battery packs that are integrated with our patented technology offer significant advantages such as: Even and effective cooling of individual cell which helps to extend their lifespan and enhance safety Charging and discharging can take place in different temperature (important for operations in temperate climates) Power and energy capacity specifications meet requirements in most EV applications. Cost reduction of at least 15%. Plug-and-play capable for quick swaps, compact, lightweight and regular shapes make it easily adapted to fit different vehicles or other applications.

Key information

Technology Category- Energy - Battery & SuperCapacitor

- Electronics - Power Management

ID Number: TO001116

Source: IPI Singapore