Battery Tech Article

Process for Rejuvenation of Spent Lithium-ion Battery Cathodes

Technology Overview

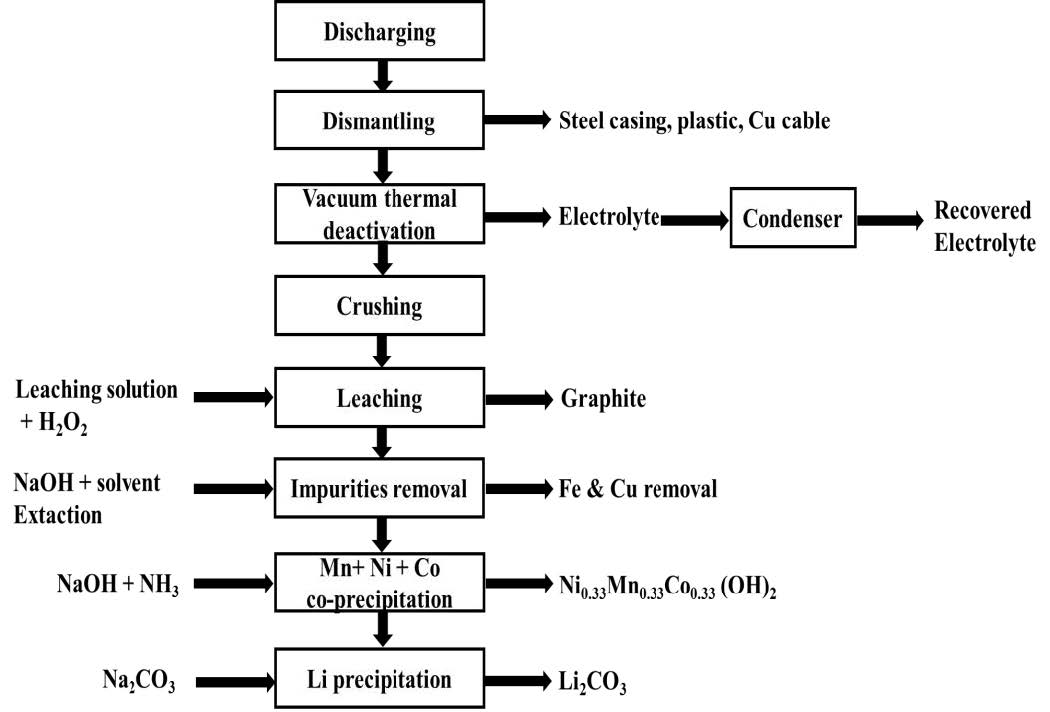

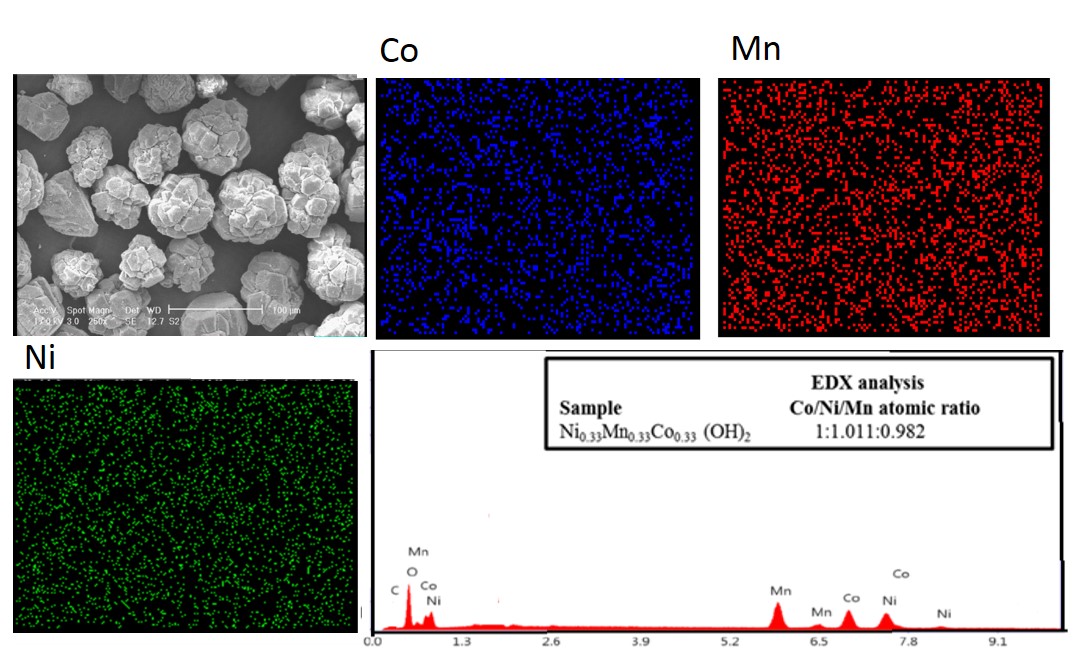

Lithium-ion batteries (LIBs) have been the preferred portable energy source in recent decades. The tremendous growth in the use of LIBs has resulted in a great number of spent LIBs. Disposal of these spent LIBs will cause serious environmental problems due to hazardous components such as heavy metals and electrolytes. Materials contained in the spent LIBs are valuable resources and could be recycled by proper technologies. Current methods are not suitable for LIB recycling due to slow process, low purity of the products (low profits) and the use of non-environmental friendly leaching reagents.The proposed LIB recycling technology is based on a co-precipitation process and control system which can process various types of spent LIBs including lithium cobalt oxide (LCO), lithium manganese oxide (LMO), lithium nickel manganese cobalt oxide (NMC) and lithium nickel cobalt aluminium oxide (NCA). The co-precipitation method allows the recovery of cathode metal salts in their original form, without separation of the metal elements. The obtained metal salts could then serve as the precursor for synthesis of new cathode material. In summary the process recovers the following products at more than 99% purity levels: (a) graphite and (b) cathode metal salts e.g. LiCo1/3Ni1/3Mn1/3O2, NiCO3, MnCO3, CoC2O4, and Li2CO3.The technology provider is seeking a partner who is willing to fund the prototype development and become an early adopter of the technology. Preferably, the partner should have access to spent LIB sources to support the trial.

Technology Features & Specifications

The co-precipitation method avoids separation of the cathode metal elements, saving cost and reduces processing steps. In contrary, traditional separation of Co and Ni metals by solvent extraction from NMC batteries involve complicated steps and is a slow method. Moreover, the separated cobalt (Co) and nickel (Ni) salts are mixed again for the synthesis of new cathode material.The technology owner expects that the profits from LIB recycling using this technology are 4 times greater than current technologies, as various types of LIB can be processed and valuable cathode precursors can be synthesised.

Potential Applications

The technology can be applied and integrated to existing LIB recycling processes to increase purity and profitability but can also served as a standalone system for LIB recycling and cathode manufacturing. Battery recyclers, cathode or battery manufacturers, government initiatives and precious metal miners will likely profit from the application of the technology.

Market Trends Opportunities

As the circular economy becomes more important and the end of life legislation starts to impact on battery manufacturers, purity and efficiency will become central. Currently, only 5% of the worlds spent LIBs are recycled and when they are not recycled to a useful level or material output, it makes recycling a non-profitable investment. There are opportunities for Singapore to disrupt this space and own IP which can drive the future of battery recycling and how precious metals are “mined”.

Key information

Technology Category- Waste Management & Recycling - Industrial Waste Management

ID Number: TO134199

Source: IPI Singapore