Battery Tech Article

Silica Fibrous Material for Sorption, Separation, Catalytic and Battery Applications

Technology Overview

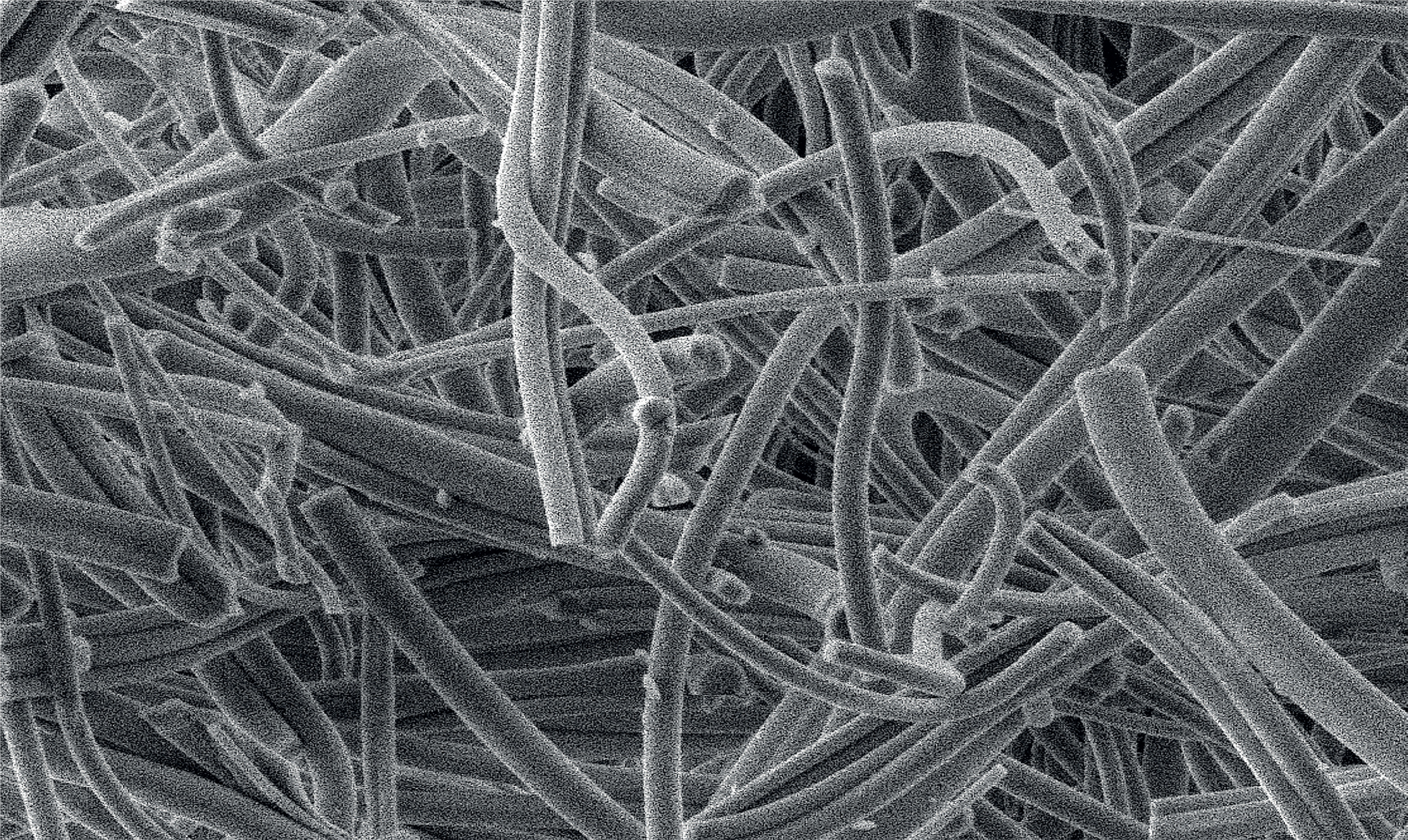

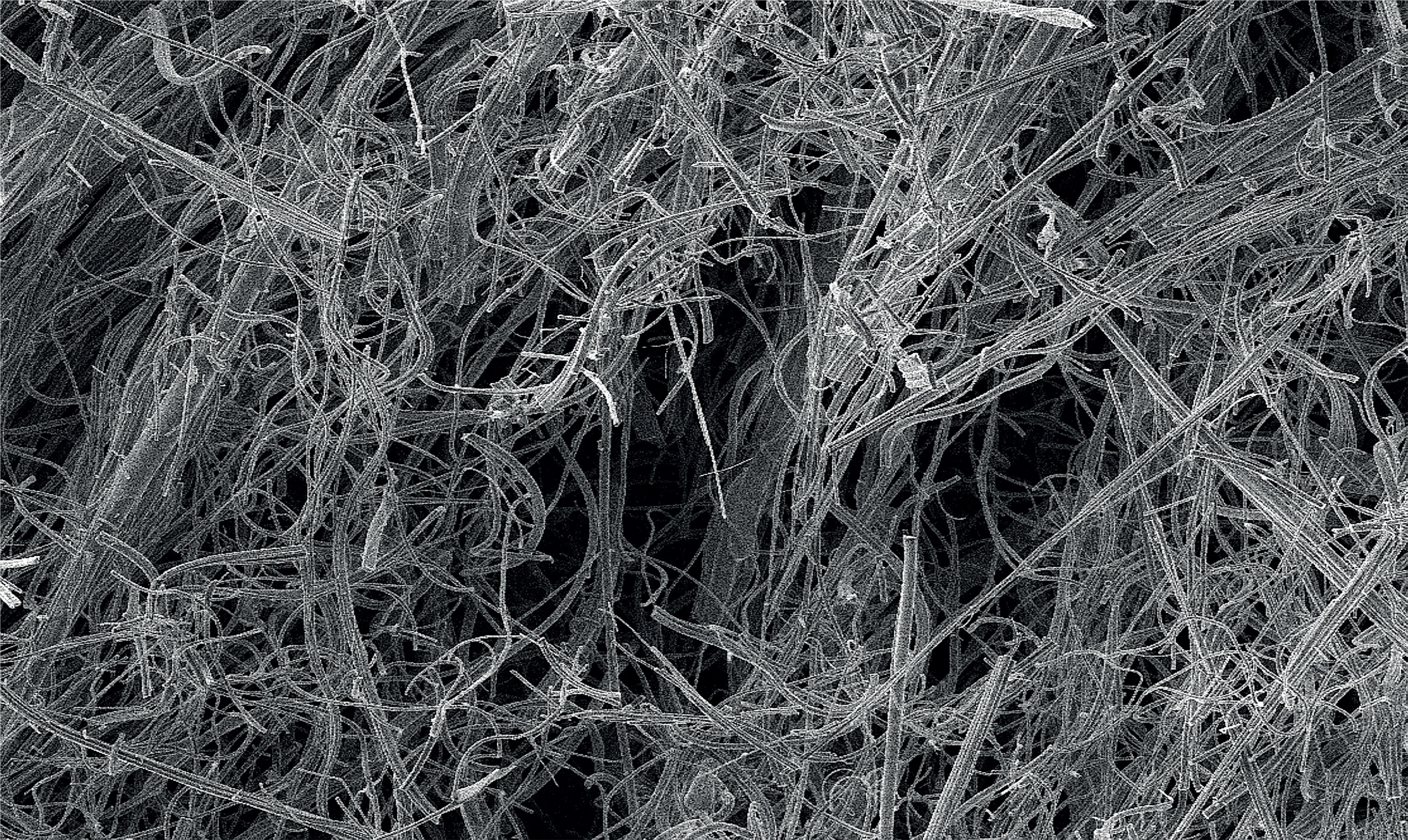

Silica (SiO2) fibrous material is a special functional material with unique properties represented by amorphous fibre structure. These silica fibres can adsorb significantly more water than commercially available silica gel of the same mesoporous character. This feature is especially apparent in the range of medium relative humidity (30-70% RH), which is industrially the most important range for adsorption (in electronics, food, chemical industries, and numerous others). Owing to its porosity, the fibrous sorbent can be desorbed for its next use at significantly lower temperature (at least 20°C lower), which has a positive effect on the cost figure of the process. High specific surface area and mesoporosity are the main advantages, and make the material especially suitable for sorption and catalytic applications. The material can also be used as an adsorbent, catalytic carrier, battery electrolyte, etc.

Technology Features & Specifications

Silica fibrous material is a special functional material with unique properties represented by amorphous fibre structure. This very fine material is produced by Centrifugal Spinning technology, which enables the production of fibres with diameters between 800 – 1200 nm. Fibres can be delivered in different modifications, either as COTTON or POWDER (after milling that leads to the fibre shortening to several microns), and can be produced in large volumes with easy and fast upscaling capacity.

Potential Applications

The SiO2 fibres have great chemical and thermal resistance, tremendous surface to volume ratio (800 m2/g), and show mesoporous characteristics. All these parameters make the fibres excellent sorbents, e.g. for absorbing undesired air moisture, which is an important process in many industries (electrical engineering, food processing, chemistry, etc.). At the same time, it is possible to easily and effectively desorb and use them repeatedly. In addition, the material can adsorb various VOCs, heavy metals and other compounds. This material has already found uses in catalytic applications, as a highly resistant battery separator, or as a special chemical and thermal resistant filtration material.

Benefits

High specific surface area (600 – 900 m2/g) and mesoporosity are the main advantages of these fibres compared to other silica fibers. This material can capture 40% more water than classic silica gel, and can be desorbed easily and cost efficiently, for its next use at lower temperatures.

Key information

Technology Category- Materials - Nano Materials

- Energy - Battery & SuperCapacitor

- Chemicals - Inorganic

- Environment, Clean Air & Water - Filter Membrane & Absorption Material

ID Number: TO059508

Source: IPI Singapore